The Ultimate Guide To Single Cavity Valve Gate Systems

Consequently, this side of the additional runner 20 b will certainly have a lot more heated thaw than the contrary side of the secondary there of. Nevertheless, as both secondary joggers 20 b obtain substantially the exact same percentages of warmed as well as relatively unheated melt, there will certainly be significantly equal mass flow through both secondary runners 20 b.

Describing FIG. single cavity valve gate systems. 6, thaw circulation downstream from section B-B, at the 2nd branch 22 b where the second jogger 20 b branches into 2 tertiary runners 24 b, is shown. As can be seen from the sectional sight, the heated peripheral portion 28 is more balanced than it was at the section B-B, because of heating of the relatively unheated side; however, there stays a significant asymmetry in terms of the level of home heating on either side of the additional jogger 20 b.

6. Describing FIG. 7 and to FIG. 8, the downstream consequences of this asymmetric division are shown in the sectional sights D-D and also E-E. Referring to FIG. 7, the sectional view D-D shows that this tertiary jogger 24 b receives a disproportionate share of the warmed peripheral melt 28, while the sectional view E-E received FIG.

The warmed melt moves quicker as it is much less viscous. Therefore, the tertiary jogger 24 b including section D-D will certainly receive extra thaw than the tertiary runner 24 b consisting of section E-E, resulting in a flow imbalance in between the nozzles as well as dental caries provided by these corresponding tertiary runners 24 b.

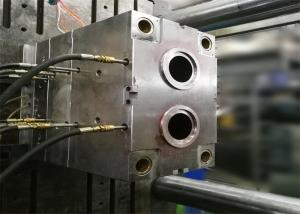

Referring to FIG. 9, there is shown in a sectional sight on P-P of FIG. 10, a flow-rotating plug 30 in conformity with an embodiment of the development. The flow turning plug 30 is set up at the juncture of the main runner 16 b as well as the set of secondary runners 20 b in the manifold 14 b.

Getting My Single Cavity Valve Gate Systems To Work

11 b, a manifold 114 b integrating the flow-rotating plug 30 of FIG - single cavity valve gate systems. 9 is revealed at an initial branch 118 b between a primary jogger 116 b as well as a pair of second runners 120 b in the jogger system 112 b. The thaw flow through the primary 116 b, secondary 120 b and also tertiary 124 b joggers will currently be explained with respect to FIGS.

11 a is comparable as well as consequently will not be described individually. The section of the thaw taken at A ′- A ′ in FIG. 11 b showing the thaw in the primary jogger 116 b upstream from the very first branch 118 b and the plug 30 will certainly be the exact same as the area A-A shown in FIG.

The Greatest Guide To Single Cavity Valve Gate Systems

Nonetheless, downstream from the very first branch 118 b and also plug 30, the sectional views differ. Describing FIG. 12, there is highlighted in a sectional view, the melt in the second runner 120 b at section B ′- B ′ (single cavity valve gate systems). The heated outer portion 28 of the second jogger 120 b is shown as shaded in.

12 to FIG. 3, it is obvious that the shaded section has been rotated 90 levels. Similarly, the sectional sight at C ′- C ′ of FIG. 11 b is revealed in FIG. 13. Compared to the similar sectional sight C-C shown in FIG. 4, the sectional sight C ′- C ′ displayed in FIG. 13 is revolved 90 degrees.

11 b, the shaded parts at sections B ′- B ′ and C ′- C ′ are both in the plane of the page, as opposed to being in an aircraft perpendicular to the web page. Subsequently, they will certainly both be uniformly split at a second branch 122 b where the second runners 120 b divide into particular sets of tertiary joggers 124 b.

Referring to FIG. 14, there is illustrated in a sectional sight, melt downstream from the sectional view B ′- B ′ at the 2nd branch 122 b where the secondary runner 120 b branches right into 2 tertiary joggers 124 b. Similar to the sectional sight of FIG. 6, the melt is asymmetrically dispersed regarding the periphery of the second jogger 120 b.

14, this unbalanced distribution is symmetrically split such that each of the tertiary joggers 124 b will certainly receive substantially equivalent halves of the warmed melt. Describing FIGS. 15 as well as 16, there is shown in sections D ′- D ′ and E ′- E ′ specifically, the thaw circulation in the tertiary runners 124 b. As is apparent from FIGS.

What Does Single Cavity Valve Gate Systems Mean?

Appropriately, the amount of melt offered to the associated nozzles by these tertiary runners 124 b will be substantially equal, as well as of significantly the exact same temperature. According to other embodiments of the innovation, the flow is not rotated in between the main jogger 116 b and also second runners 120 b, yet is instead revolved in between the second joggers 120 b as well as tertiary joggers 124 b.

official website check my source go now